Download Article Horizontal motion conveyors replaced horizontal bucket elevators and reduced maintenance costs for a food manufacturer. We are guilty of it. We have published articles, infographics, and ads, and given talks about Total Cost of Ownership (TCO) and Return ...Continue Reading

News and Articles

Check out the latest news from Triple/S Dynamics.

Filters:

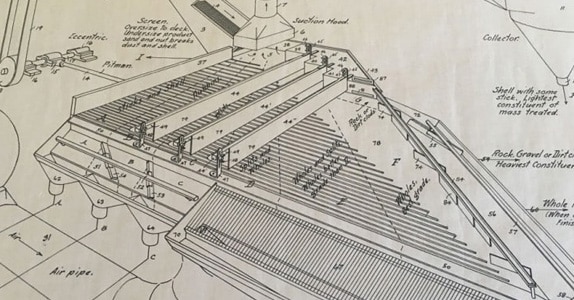

Dry separation equipment first appeared over a century ago when Edwin Steele and Henry Sutton invented the Specific-Gravity Separator. Dry separation equipment first appeared over a century ago when Edwin Steele and Henry Sutton, principals at Sutton, Steele & Steele, ...Continue Reading

While most engineers in the dry process industry know what a gravity separator does, precisely describing how it works can be difficult. While most engineers in the dry process industry know what a gravity separator does, precisely describing how it ...Continue Reading

The ongoing costs after you’ve written the check for that piece of capital equipment are just as important as the purchase price. They’re everywhere — in the news, at association meetings, in advertisements, in conference rooms, and on agendas — ...Continue Reading

DRY SEPARATION BY FLUIDIZATION Any complex dry granular mixture, in a fluidized bed, can be separated into component fractions on the basis of one of three particle characteristics – density, shape or size – so long as two of the ...Continue Reading

This paper describes the application of vibrating conveyors to the handling of ash from mass-burn incinerators. The characteristics of two different kinds of conveyor, the natural frequency vibrating conveyor and the differential velocity, or “horizontal differential” conveyor, are compared. Factors ...Continue Reading

Jay Sullivan Triple/S Dynamics Finding equipment that can smoothly and efficiently move a fragile, easily agglomerated, dusty, or light-density dry bulk material, a material with interlocking shapes, or a blend of materials with widely varying bulk densities can present an ...Continue Reading

A horizontal-motion conveyor can smoothly and efficiently move a huge variety of materials, such as polymers, hot potash, borax crystals, potato chips, and breakfast cereal, without damaging, segregating, stratifying or aerating them. This article answers common questions about horizontal-motion ...Continue Reading

Tim Talberg Triple/S Dynamics Accumulating equipment can eliminate production slowdowns and improve process efficiency by temporarily storing dry bulk material during process interruptions and holding it for later release, After describing various types of accumulating equipment, this article explains how ...Continue Reading