Conveying & Screening for the Chemical Industry

The chemical industry creates an immense variety of products touching virtually every aspect of our lives. While many of the products from the industry, such as detergents, soaps and perfumes, are purchased directly by the consumer, 70% of chemicals manufactured are used to make products by other industries including other branches of the chemical industry itself.

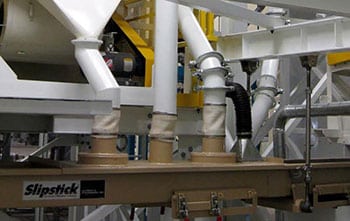

Today, chemical processors face a variety of challenges from dust containment, high temperatures, and product degradation. Triple/S Dynamics manufactures equipment specifically designed to address these issues and more, including the Slipstick Horizontal Motion Conveyor and the Texas Shaker Vibrating Screen.

Applications in the Chemical Industry

Catalyst

Conveying & Screening Catalysts

From conveying fragile calcined catalyst on a Slipstick Horizontal Motion Conveyor to screening catofin catalysts in five fractions at 20,000 PPH on a Texas Shaker Vibrating Screen, Triple/S Dynamics experience with this product can benefit your application.

Fertilizers / Pesticides

Conveying Fertilizers & Pesticides

Right now, the Slipstick Conveyor is conveying fertilizers and weed killers at plants around the world. Processors like the Slipstick because of its gliding motion that does not create more dust, can be designed in a rectangular enclosed tube and its ability to move product at high volumes.

Potash

Screening Potash

Potash is any of various mined and manufactured salts that contain potassium in water-soluble form. The name derives from pot ash, which refers to plant ashes soaked in water in a pot, the primary means of manufacturing the product before the industrial era.

Today, the Texas Shaker Vibrating Screen, some designed for sizing potash at more than 600 TPH in one machine, are at work at some of the largest producers in the U.S. and Canada.

Plastics

Conveying & Screening Plastics

Today, we are surrounded by plastics. While we are all familiar with plastic packaging of every product, so does the automotive industry, plastics in the electronic devices that fill our homes, the construction industry from roofing granules or plastic bolts and nuts, the use of plastics and resins is everywhere. Triple/S Dynamics offers many solutions for plastics and resins manufacturers from conveying phenolic resins, wet fiberglass, flake resins, silicon beads, or plastic pellets with Slipstick conveyors.

We’ve also supplied conveyors with screening sections to screen out small (undersize) pieces of rubber. Sutton Density Separation equipment has played a role in the recycling industries for decades – cleaning and separating plastics from metals like copper or aluminum.

Resins

Conveying Phenolic Resins

Phenolic resins are found in a myriad of industrial products. First used as the basis for Bakelite, phenolic resins were the first commercial synthetic resins (plastics). They have been widely used for the production of molded products including billiard balls, laboratory countertops, and as coatings and adhesives.

A producer of phenolic resins came to us to help him solve a problem with dust created by his screw conveyor. Find out how the Slipstick Conveyor cut his dust problem in half.

Salt

Screening & Conveying Salt

Triple/S Dynamics equipment has been screening and conveying salt, in various forms, for over thirty years. From conveying table salt to flakes or screening to size salt pellets, the Slipstick Conveyor and the Texas Shaker Vibrating Screen have performed exceptionally well for decades.