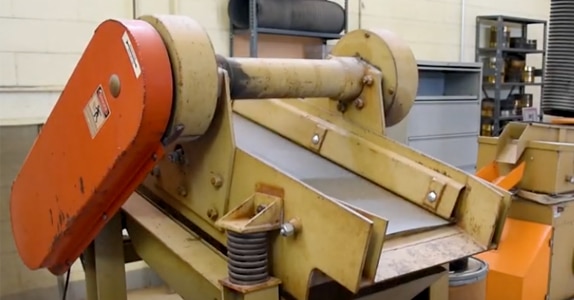

High-Capacity Potash Screening Success in the Middle East

Solutions Center

For Your Material Handling Challenge

Browse our solutions center to discover how Triple/S Dynamics continues to solve our customers material handling challenges with innovative conveying, screening and separating equipment. We work with our customers to produce everything from breakthrough concepts down to simple tool-less fixes.

Filters: