Old Dutch Foods

Conveying Pretzels without Product Breakage

Customer Challenge

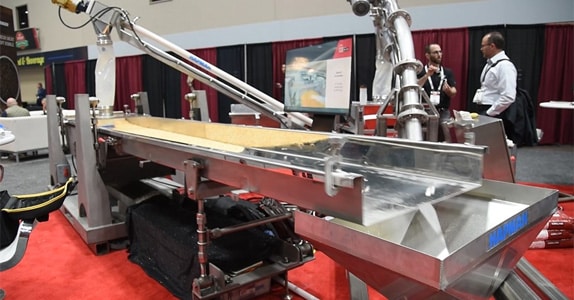

First Rate Industries is a family-owned, full service millwright company specializing in the feed, grain, and pet food facilities as well as having a proven record of excellence in complete turnkey operations. First Rate Industries had an application to move finished pretzels from processing to packaging at a large snack manufacturing facility. Triple/S Dynamics was to provide a proposal to compare with two other companies that could not provide equipment to do the longest length. Convey finished pretzels from processing to packaging.

Replaced existing belt conveyors with Slipstick horizontal motion conveyors (HMC) to reduce product breakage, salt loss and tailings on the floor.

Triple/S Solution

Triple/S Dynamics designed a support structure to suspend 4 parallel conveyor runs above 20 ft wide bay to keep area below the conveyors open for forklift traffic and storage. It also has removable covers clamped to pan for ease of access.