Old Dutch Foods

Conveying Copper Chloride Powder

Customer Challenge

A global animal feed ingredient producer, for beef, dairy, poultry, and swine nutritional supplements, contacted Triple/S Dynamics with a project they were working on in a new bagging area within their plant. The project included transferring materials from five silos, located indoors, in-line horizontally, to a new automated bagging area, where previously it was a manual bagger operation. Our customer stated that the conveyor cannot break up the material, as such, screw conveyors and pneumatic transfer conveyors were not an acceptable option for them.

Triple/S Solution

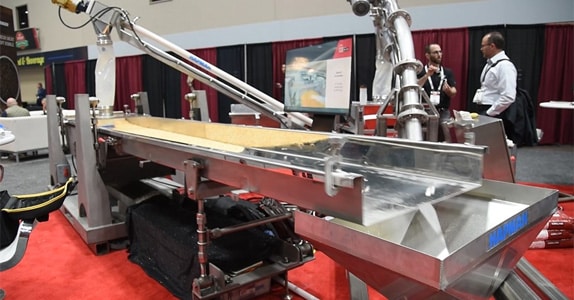

Once it was determined a good fit with easy access, Triple/S Dynamics designed a Slipstick Horizontal Motion Conveyor, 24”W x 6” D x 60’ – 6 3/4”L to transport the copper chloride powder from five silos to two automatic bag filling lines.