Old Dutch Foods

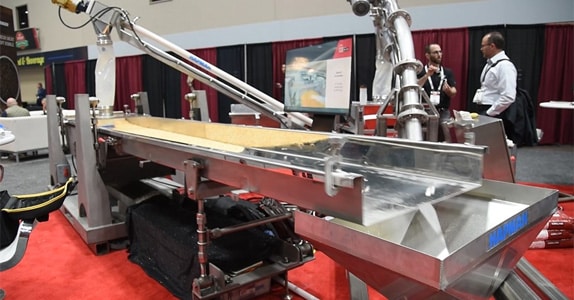

Conveying Candy

Customer Challenge

A top candy maker and distributor contacted Triple/S Dynamics after visiting our website and viewing our processing equipment videos. They were looking to replace their existing belt conveyors handling both wrapped and unwrapped candy. The existing belt conveyors had tracking issues which would fray the edges of the belt and they were also experiencing issues with fines from product building up on the conveying surface of the belt conveyor making it hard to clean. The replacements would be part of a two phase project. The first phase would be to replace an existing 8” wide by 7’ foot long belt conveyor handling chocolate frap chips and the second phase would be to replace three, 70 foot long belt conveyors with one conveyor handling wrapped candies.

Triple/S Solution

Triple/S Dynamics performed multiple lab tests with various product samples of wrapped and unwrapped candy supplied by the customer to measure bulk density and conveying velocity. After testing, Triple/S Dynamics made a site visit to review the customers’ current processing layout and to discuss options for replacing the existing belt conveyors.