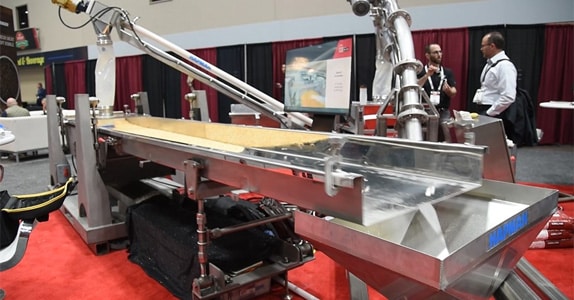

Old Dutch Foods

Conveying and Accumulating Snack Crackers

Customer Challenge

A major food manufacturer had an existing conveying system designed and installed in 1997. The plant was being updated and redesigned for more capacity.

Triple/S Solution

T/SD engineers were involved with the plant on site and recommended a layout that including 11 new conveyors in the first phase and 4 more in the second phase. All welds will be continuous and ground smooth to 150 grit finish, T/SD Class IV weld finish.