Old Dutch Foods

Improved Sanitation Through Retrofit

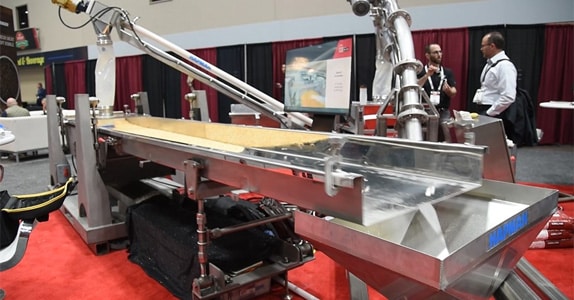

A well-known food producer was fed up with having to get out the tools and disassemble the gates every time its conveyors needed cleaning. The customer approached Triple/S Dynamics, Dallas, Texas, and provided the company with the challenge of reducing downtime by easing assembly and disassembly time.

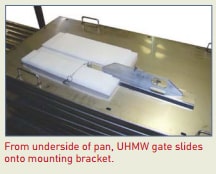

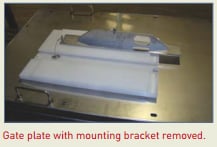

Triple/S Dynamics supplied conceptual retrofit design drawings for customer review and used customer feedback to finalize the design over a four to six week period. Once the collaboration produced a satisfactory prototype, Triple/S fabricated and shipped the new gate parts in less than a month. The new gate parts were designed for minimal field rework to the existing conveyors and were installed in a day. The retrofit surpassed the customer’s expectations in that the gates were now tool-less, easy to clean, lighter weight and interchangeable. They were so pleased they purchased several retrofit kits for field modifying their existing conveyors and purchased new conveyors with the redesigned gates.

Triple/S added the new gate design to its equipment line and now markets the retro- fit to existing Slipstick conveyor owners.

-PMT: March/April 2013