Old Dutch Foods

Conveying and Scalping Raw Almonds

Customer Challenge

The California almond industry is growing at an exponential rate and producers are expanding and updating their processing plants to increase output as quickly and efficiently as possible to meet consumer demand. An existing customer in the almond hulling and shelling operations needed to increase capacity up to 60 tons per hour while scalping out dirt, leaves, and branches.

Triple/S Solution

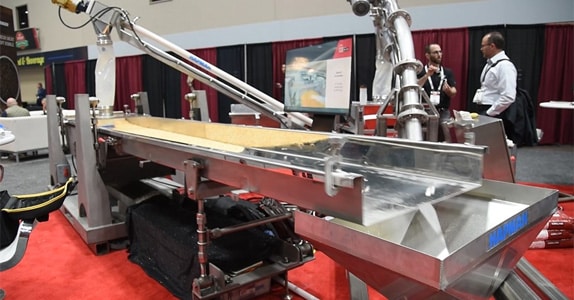

Triple/S Dynamics designed a Slipstick Horizontal Motion Conveyor, 60”W x 48”D x 19’- 11”L, carbon steel pan design, featuring carbon steel floor support structures, end mounted 15/5.0 drive unit, a 5 foot declining grizzly bar section to scalp off dirt, leaves, and branches and dual product discharges beneath the pan to discharge product in two different directions.