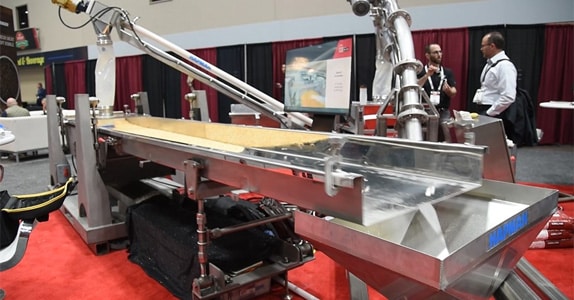

Old Dutch Foods

Conveying Crackers with Little or No Product Loss

Customer Challenge

A large ready-to-eat cereal/snack manufacturer needed to replace two existing belt conveyors to reduce product breakage and tailings on the floor. These belts move finished crackers to packaging.

Triple/S Solution

Triple/S designed the Slipsticks inclined to accommodate existing feed and take-away conveyors. The Slipstick is known for its gentle conveying with no product breakage, dust generation or segregation. Other benefits ofthe Slipstick over belt conveyors are listed in the brochure below.