Screening Out Fines From PET Flakes...

Shifting Markets

Cooperative Add Rail Terminal to Take Advantage of BNSF Rail Line

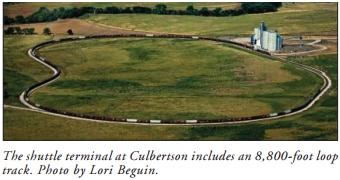

When the Frenchman Valley Farmers Cooperative looked to expand beyond local truck markets, a new rail shuttle-loading terminal with an 8,800-foot loop track gave the 22-location cooperative that ability.

The terminal at Culbertson, NE, with 2.32 million bushels of storage, was constructed to give the coop access to a Burlington Northern Santa Fe (BNSF) main line, says Mark Friehe, branch manager for both the new elevator and a coop elevator at McCook, NE.

“Having a rail terminal in Culbertson gives Frenchman Valley access to Gulf and coastal rail markets we haven’t had in the past,” Friehe says. “The advantages in pricing and rail rates will give our patrons the best opportunity to get a better premium for their grain.”

Construction on the $18 million facility (308-278-2410) was started in June 2012, and it was completed in time for fall harvest in August 2013. Frisbie Construction Co., Inc., Salina, KS (785-536-4288), served as the main contractor on the project.

“We chose Frisbie Construction because of their reputation for quality and the ability to take on project as large as Culbertson,” says Friehe, who has been with the coop for 18 years.

Besides the BNSF connection, the new shuttle site also is served by the Nebraska, Kansas & Colorado Railway, which also connects with several other Frenchman Valley locations and will provide the ability to ship grain from these locations, Friehe adds.

“The facility at Culbertson isn’t built for long-term storage,” Friehe says. “We will try to turn the facility as much as possible and with improving yields, we will be able to turn the facility more frequently.”

Storage

The terminal’s 2.32 million bushels of storage includes four McPherson Concrete jump-form concrete tanks, a GSI corrugated steel tank, and a 1-million-bushel ground pile.

The four McPherson tanks are 60-feet in diameter and hold 280,000 bushels each. Each of these flat-bottom tanks stand 120 feet tall, with aeration being provided by two 50-hp AIRLANCO centrifugal fans and three 2-hp roof exhausters at 1/10 cfm per bushel on coarse grains. The tanks are equipped with 10,000-bph GSI bin sweeps for clean-out.

The GSI corrugated steel wet tank is 59.7 feet in diameter and holds 200,000 bushels. The flat-bottom tank stands 80 feet tall at the eave and 96 feet tall at the peak. The tank has outside stiffeners and is emptied into a below ground GSI 10,000-bph drag conveyor.

Neither the concrete nor steel storage tanks are equipped with temperature monitoring systems because of the expected quick turnover rate, Friehe says.

Storage also includes a 600-foot diameter, 1-million bushel LeMar temporary storage pile. The system has 8-foot perforated steel walls, a GSI 80-foot-tall support tower, and a clay-based floor. Currently, the temporary storage is emptied out by front-end loaders, but future plans call for a conveyor to be installed under the pile.

Grain Movement

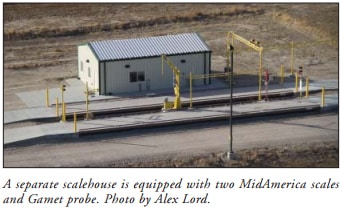

Incoming trucks are weighed on a 80-foot MidAmerica Scales pitless scale adjacent to the shuttle site’s office building. A Gamet Apollo truck probe takes a sample for grading at the inbound scale. An adjacent MidAmerica truck scale with a kiosk printer system is used for outgoing trucks.

The terminal has three receiving pits — two 800-bushel mechanical receiving pits for trucks and a rail receiving pit. All three pits feed two, 17,000-bph GSI receiving legs equipped with 20×8 TAPCO buckets on 21-inch belts.

The receiving legs deposit grain into a 12-duct Schlagel swing-set electric distributor. From there, grain travels via GSI 20,000-bph enclosed belt conveyors to concrete, steel, or temporary storage. Grain can also be run through a 20,000-bph Triple/S Texas Shaker grain cleaner prior to going to storage.

Wet grain can be sent via 10,000-bph wet leg to a continuous flow Zimmerman dryer, rated at 10,000-bph for taking three points of moisture off of corn. The dryer is fired by three propane storage tanks totaling 86,000 gallons that also serve as a terminal site for coop’s customers.

The concrete and steel storage tanks empty onto 60,000-bph above-ground GSI belt conveyors running back to the receiving legs and a 60,000-bph GSI load-out leg equipped with three rows of 20×8 TAPCO buckets. The load-out leg feeds a 60,000-bph C&A bulk weigh scale with extended upper and lower garners (3,300 bushels each). The scale utilizes C&A software. Workers atop railcars are protected by a Fall Protection Systems’ trolley unit that runs the length of 2-1/2 railcars.

According to Friehe, the bulk weigh scale is set up to run 28,000-bushel batches and a railcar can be filled in less than four minutes.

In addition to rail load-out, Frisbie built two 5,000-bushel steel square hopper bins located above the receiving pits for truck load-out.