Screening Out Fines From PET Flakes...

Hopkinsville Elevator Gets Double Shot From Texas Shaker Vibrating Screen

Most people don’t think about clean corn when they pour a cocktail. But that is not the case at Hopkinsville Elevator in Hopkinsville, KY, where employees are thinking about clean corn 24 hours a day, 7 days a week. Hopkinsville provides one of three ingredients used in the production of whiskey: clean whole corn.

Hopkinsville Elevator began in 1968, when a small group of farmers developed plans for the forming of Hopkinsville Elevator as a cooperative. Approximately 180 investors proceeded to buy an existing grain facility to serve their needs. This facility had served the area for a number of years and had a capacity of 634,000 bushels. From this recent beginning the elevator had grown in membership to more than 2300 patrons in 34 surrounding counties. The elevator system has a combined storage capacity of over 15 million bushels, with additional locations at South Union, Russellville, Casky, and Guthrie in Kentucky, and a barge-loading facility at Clarksville, TN.

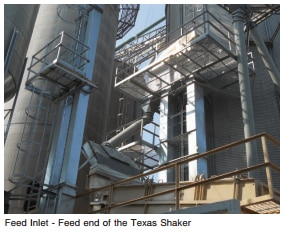

In 2011, the elevator set out to double the cooperatives cleaning capacity by adding a new grain cleaner at the South Union location. The company chose a Texas Shaker vibrating screen from Triple/S Dynamics for its distillers’ corn production. Triple/S sized a 6×10-ft, eight-deck arranged to scalp cob pieces and reduce F.M. to less than 1%, at 10,000 bushels/hr of dry shelled corn. The 6×10-ft screen decks are in four parallel sets of two, scalping through ½-in.-diam round holes and cleaning on ¼-in. clear opening woven wire screens. The dual purpose screen scalps corn across 240 sq ft of screen area, and cleans across 240 sq ft. The incoming stream is automatically divided into four equal streams discharging onto the scalping screens. The corn passes through the ½-in.-diam scalping screen that retains the cob pieces, and over the ¼-in. cleaning screen to separate the foreign material and chips. The coarse product and fines discharged from each of the four sets are brought together and discharged through three separate chutes – oversize, product, and undersize.

The Texas Shaker oscillates in a straight horizontal line, 1 in. at 475 rpm. The gentle action is best for efficient screening. The screen decks are inclined downward at six degrees. Self-cleaning, removable ball decks resist blinding. Live rubber balls confined in grids under the screens bounce against the screens to prevent blinding with pieces getting stuck in the openings. The attached vibrator module comprises two parallel gear-coupled unbalanced shafts, which counter-rotate to generate a straight-line inertia force. This makes it self-balancing; the inertia forces are absorbed in the motion of the machine. The shafts are mounted in spherical roller bearings and completely enclosed. Texas Shaker models are fully enclosed and dust-tight.

The Texas Shaker went into Hopkinsville in July of 2011. When asked if the new cleaner had met the company’s expectations, Andy Newton of Hopkinsville said, “No. It is better than we expected. It’s cleaning out more fines than we ever anticipated and it is exceeding the capacity promised by Triple/S.”

-Powder Bulk Solids: October 2012