Old Dutch Foods

Slipstick Conveyor Increases Line Yields

A major coffee manufacturer suffered from decreased line yields and an increase in clean up time using a vibratory overs screener. An excess portion of quality product was being screened to scrap and the enclosed belt conveyor was hard to clean due to the lack of accessibility. The belt conveyor was totally enclosed to contain dust.

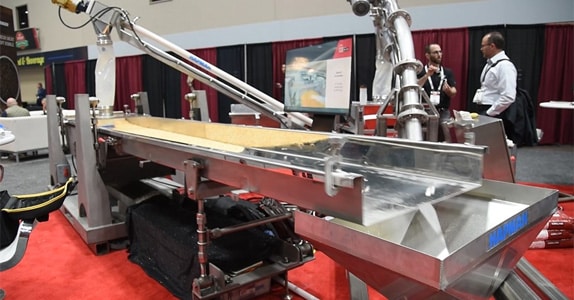

Triple/S Dynamics installed two Slipstick horizontal motion conveyors to solve the series of problems. The gentle conveying action of slow advance, quick return motion is easier on the product. The stainless steel sanitary conveyor pan trough is equipped with hinged covers for dust containment and the covers have quick release latches for ease of cleaning access. The Slipstick is designed for long, trouble-free service life. Mechanically, it’s based on a minimum of moving parts, with the fully enclosed drive mechanism consisting only of bearing-mounted, gear-coupled shafts. Durability is ensured through our dedication to solid construction throughout.

The result of the Slipstick conveyors is screen blinding dramatically decreases which results in reducing the amount of good product being bypassed to scrap. And increased productivity and decreased clean up time were the expectations of the coffee manufacturer.